Durable adhesive bonding paired with the flexibility to effortlessly debond. Whether for reworking in production, repairing or reusing and recycling components: Lohmann is also there for you as a development partner beyond successful bonding!

Video “Residue-free removal of scanner rails in supermarkets”

Repair- and recycling-friendly design is becoming increasingly important. Legal requirements such as WEEE, the EU Green Deal or especially the Battery Pass require ever more sustainable processes and products. Lohmann helps you to implement sustainable products efficiently - with the simplest possible integration into existing product design and manufacturing processes.

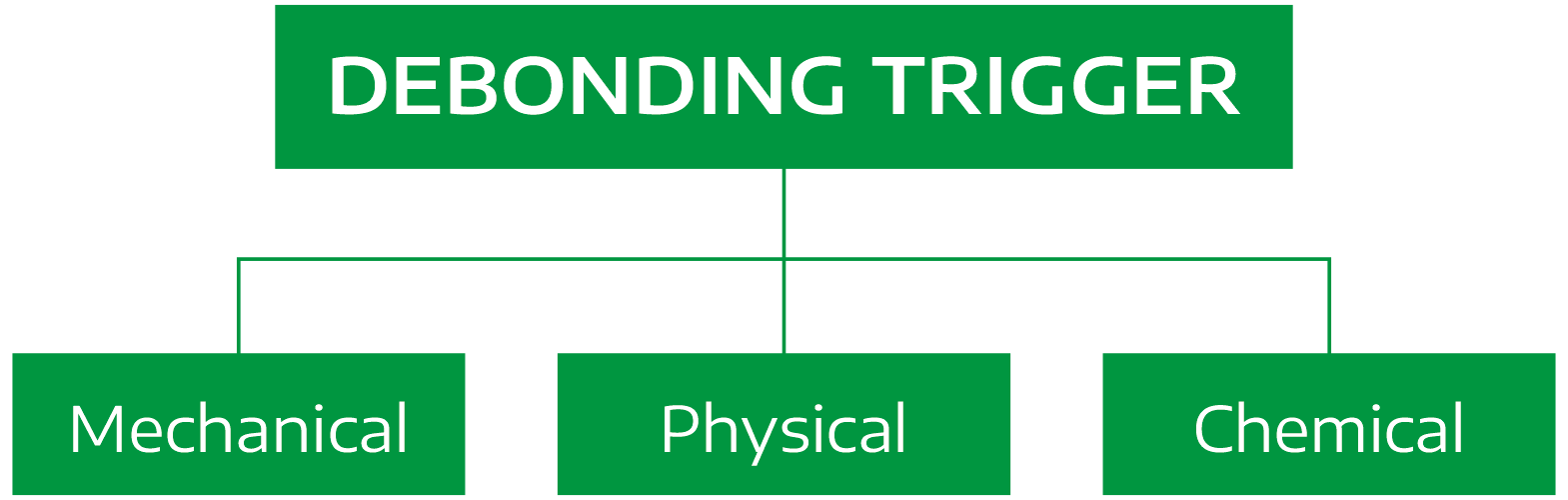

Debonding on Demand is a collective term for release mechanisms (triggers) for adhesive bonds. The DIN/TS 54405 standard differentiates between three trigger categories. The selection depends on the requirements of the application. Debonding-capable solutions meet the high demands placed on the bond, while the bond can be selectively released if required.

Lohmann already serves more than 10,000 applications with over 700 bonding system variants. As individually designed as these variants are, as individually we support you in the development and implementation of Debonding on Demand solutions.

Debonding on Demand enables

Debonding on Demand solutions simplify dismantling and reworking in production and application by allowing bonds to be removed quickly, gently and without leaving any residue.

Scanner rails in supermarkets, for example, are mounted with foam adhesive tapes. Conventional products usually leave adhesive residue behind when they are removed, which is difficult to clean. New adhesive foam tapes from Lohmann with an integrated reinforcing film now make it possible to remove scanner rails easily and without leaving any residue.

Debonding on Demand enables

It is becoming increasingly important to make products repairable without significantly changing their design or manufacture. This is particularly true against the backdrop of EU directives on the circular economy such as WEEE, the Battery Pass or the Green Deal.

Lohmann's Hook&Loop solutions in double-sided adhesive tapes enable efficient production with reversible bonding. This facilitates tool-free maintenance and cleaning, e.g. for dishwasher panels.

Debonding on Demand enables

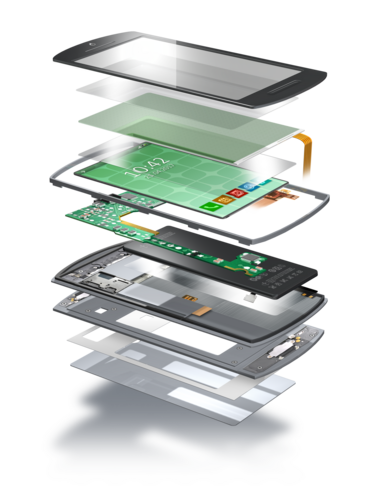

Similar to reparability, the regulatory requirements for the recyclability of products are increasing. This applies in particular to electronic devices such as smartphones, whose batteries already have to achieve a 90% recycling rate.

Innovative debonding solutions using UV light or temperature, for example, enable components to be separated gently. These remain intact and can be replaced, reused or recycled according to type. This reduces electronic waste, the ecological footprint and costs.

We offer solutions for a wide range of industries when it comes to implementing sustainable requirements. Whether residue-free removal or repairable or recyclable products, we develop tailor-made solutions with you. Your contact Peter Harendt (Head of Application Technology) looks forward to receiving your individual inquiry.